Pultrusion

3. Equipment

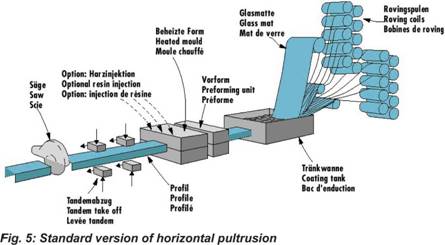

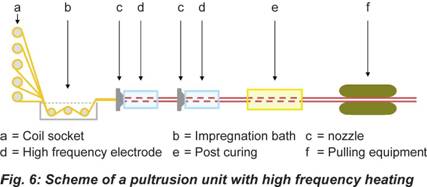

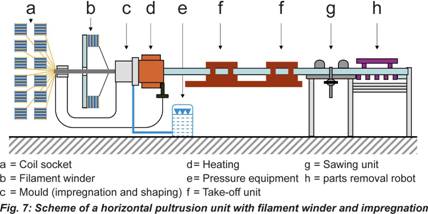

Equipment includes warp creels and suspensions for two-dimensional reinforcing materials, impregnating units with a variety of auxiliary impregnating equipment, guide elements to feed the reinforcements into the pultrusion moulds, as well as a variety of take-off elements and sawing devices. Specific technical know-how with regard to individual plants is reflected in the respective equipment design and lay-out.

Several of these plants are charted below. Yet there are comparatively few plants being offered; most of the plants used in this context were constructed by the respective profile manufacturers themselves.

PULTRUSION UNITS – MOULDS

Pultrusion moulds made of high-alloy steels are approximately 0.75 to 1.5 m long; their width and height correspond to the profile cross-sections and are subdivided into several sections. The interior is frequently polished and chrome plated in order to ensure low frictional resistance and good surface quality.